PRODUCT PARAMETERS

Description

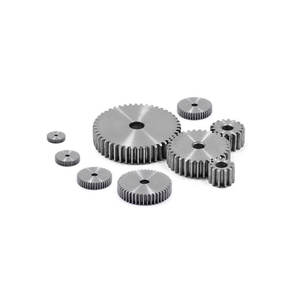

Overview of Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Partssystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Partsmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts)

Specifications of Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts

Custom Steel Transmission Planetary Gear Sets and Spur Gears are built for heavy-duty performance. These gearbox parts are made from high-grade alloy steel. The material ensures strength and resistance to wear. Heat treatment processes like carburizing or nitriding are applied. This improves surface hardness and extends service life. Precision machining guarantees tight tolerances. Each gear meets exact specifications for smooth operation. Dimensional accuracy is checked using advanced measuring tools. Errors are kept within microns to prevent misalignment.

Planetary gear sets include sun gears, planet gears, and ring gears. Components work together to distribute load evenly. This design handles high torque levels efficiently. Spur gears feature straight teeth cut parallel to the gear axis. Teeth profiles are optimized for minimal noise and vibration. Both gear types are compatible with industrial gearboxes. They suit applications in automotive, manufacturing, and energy sectors.

Surface finishes are smooth to reduce friction. Lubrication retention is improved through precise grinding. Gears undergo rigorous testing under simulated loads. Durability is verified through stress analysis and fatigue testing. Torque capacity ranges from 500 Nm to 5000 Nm. Custom ratios and sizes are available. Clients can specify tooth counts, diameters, and bore dimensions.

New-condition parts are free from defects or prior use. Raw materials are sourced from certified suppliers. Quality certifications like ISO 9001 ensure consistency. Protective coatings prevent rust during storage and shipping. Parts are packed securely to avoid damage in transit.

Customization options include modifications for specific operating conditions. High-temperature environments or corrosive settings are accommodated. Special coatings or material grades are available on request. Technical support is provided for integration into existing systems. Compatibility checks ensure proper fitment with other gearbox components.

Performance data covers efficiency ratings and power transmission limits. Gears are designed for minimal energy loss. Efficiency typically exceeds 95% under optimal conditions. Maintenance requirements are low due to robust construction. Regular lubrication is the primary upkeep need.

These gear sets and spur gears are replacements or upgrades for worn machinery. They restore gearbox functionality without downtime. Bulk orders are accepted for large-scale projects. Lead times vary based on complexity and quantity. Samples can be provided for quality verification before full production.

(Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts)

Applications of Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts

Custom steel transmission planetary gear sets and spur gears in new condition serve critical roles across industries. These components handle high torque, distribute loads evenly, operate efficiently in tight spaces. Planetary gear systems feature a central sun gear, planet gears, a ring gear. This design allows compact power transfer, making them ideal for automotive transmissions, heavy machinery, wind turbines. Spur gears have straight teeth mounted on parallel shafts. They provide simple, reliable motion transfer in conveyor systems, industrial equipment, clock mechanisms.

Steel remains the preferred material for these gears. It offers strength, wear resistance, long-term durability. Custom manufacturing ensures precise fits for specific applications. Gearbox parts in new condition guarantee zero wear, optimal alignment, seamless integration with existing systems. Industries like construction rely on planetary gears for excavators, cranes. Automotive manufacturers use them in automatic transmissions for smooth gear shifts. Renewable energy systems depend on custom spur gears to maintain consistent power output in wind turbines.

New-condition spur gears reduce noise during high-speed operations. Their straightforward design minimizes energy loss. Planetary gears excel in applications needing variable speed control. Robotics, aerospace equipment use these gears for accurate motion management. Both gear types undergo strict quality checks. Surface treatments like carburizing or nitriding enhance hardness. Lubrication channels get machined into components to prevent overheating.

Replacing worn gears with new parts avoids unexpected breakdowns. Factories see improved productivity. Maintenance costs drop. Custom options let engineers adapt gear ratios, sizes, tooth profiles. This flexibility supports unique industrial needs. Planetary gear sets handle extreme loads in mining drills. Spur gears drive agricultural machinery without slipping.

These gearbox components suit high-demand environments. Performance stays consistent under stress. Proper installation ensures maximum efficiency. Suppliers provide detailed specifications for compatibility. Businesses prioritize new gears for critical machinery. They ensure reliability, reduce downtime, extend equipment lifespan.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts

Custom steel transmission planetary gear sets and spur gears are built for heavy-duty use. High-grade steel ensures strength. These parts handle high torque and stress. They last longer than standard gears. Precision machining reduces wear. Proper maintenance extends their life.

These gears fit many gearbox models. Exact specs depend on the application. Buyers need to check size, tooth count, and mounting details. Custom orders match specific requirements. Compatibility is confirmed before shipping.

Heat treatment improves hardness and durability. Surface treatments like carburizing prevent corrosion. Each gear undergoes quality checks. Testing includes load capacity and alignment. This ensures reliable performance under extreme conditions.

Regular lubrication is critical. Use oils or greases recommended by the manufacturer. Inspect gears for wear or damage during routine maintenance. Replace components showing cracks or pitting. Clean gear systems to avoid debris buildup. Proper care prevents unexpected failures.

These gears suit industrial machinery, automotive systems, and heavy equipment. They work in robotics, construction gear, and agricultural machines. Applications needing precise power transmission benefit most. Custom options adapt to unique operational demands.

(Custom Steel Transmission Planetary Gear Set and Spur Gears New Condition Gearbox Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Gear Shift Knob 5 Speed shift lever Mat Chrome For Renault Clio Mk4 Oem 328657531R

HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear

HXMT Agriculture Rotavator Spur Gear Rotavator Side Gear Set From Shenzhen

A5840 Worm gear box reducer for dc geared motors 8mm shaft right angle speed-down gearbox reductor stepper worm gear motor part

China Hot Powder Metallurgy Motor Gear Stainless Steel Gear Parts Powder Metallurgy Gear