PRODUCT PARAMETERS

Description

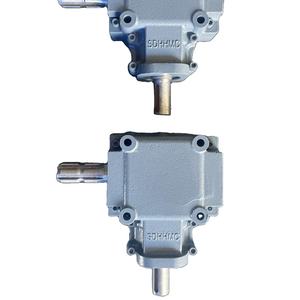

Overview of High precision micro small rack and pinion gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of High precision micro small rack and pinion gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: High precision micro small rack and pinion gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern High precision micro small rack and pinion gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(High precision micro small rack and pinion gear)

Specifications of High precision micro small rack and pinion gear

These mini shelf and pinion gears supply extreme precision in really limited spaces. They take care of requiring movement control work perfectly. The shelfs are extremely little. Pinion sizes commonly begin below 5 millimeters. Shelf lengths differ extensively. You can get brief sections or lengthy constant strips. Both shelfs and pinions can be found in difficult materials. Stainless steel is common for stamina and enduring usage. Hardened steel provides also much better use resistance. Some work need lighter weight. Aluminum alloy versions work well below.

Precision is the bottom line. Tooth accounts are cut extremely exact. This reduces reaction dramatically. Reaction is the small wiggle in between teeth. Reduced reaction means smoother motion. It likewise implies a lot more specific placing every single time. Surface area coatings are extremely smooth. Teeth are ground or refined thoroughly. This reduces rubbing. It also cuts down sound during operation. Performance improves on the whole. The gears run cooler as well.

Placing is uncomplicated. Racks normally have pre-drilled holes. Pinions place on common motor shafts easily. Several shaft sizes are available. This makes including them to existing setups simple. You can use one pinion on a shelf. Or utilize multiple pinions on one lengthy shelf for intricate activities. They fit completely right into small devices. Medical instruments rely on their accuracy. Robotics utilize them for exact joint control. Optical equipment requires their smooth activity. Automation systems incorporate them for trustworthy tiny motions. They supply trustworthy, high-precision straight movement where space is limited.

(High precision micro small rack and pinion gear)

Applications of High precision micro small rack and pinion gear

High precision micro rack and pinion gears are little mechanical parts. They are vital for numerous makers needing exact motion in little spaces. These equipments alter turning movement into straight-line activity. They do this extremely properly. Their small size and precision make them unique.

One essential area is medical devices. These equipments manage devices inside medical robots. They move continuously for fragile operations. They additionally position samples in laboratory testing makers. Accuracy is critical below. Tiny mistakes can spoil results.

Factory automation depends greatly on these mini equipments. They position parts in assembly makers. They assist cutting devices on mini CNC equipments. They relocate sensors and probes for top quality checks. Pick-and-place makers utilize them to place small electronic components. Speed and repeatability are crucial.

Optical tools uses these exact gears too. They change lenses and mirrors in microscopes and electronic cameras. They concentrate laser beams exactly where needed. This needs smooth, vibration-free motion. Also the smallest shake obscures the picture.

Robotics, especially tiny robots, take advantage of these equipments. They provide joint motion in robot arms. They help grippers open and close exactly. Little drones utilize them for control surface area adjustments. Reliable, accurate activity is non-negotiable.

These equipments are additionally located in clinical instruments. They move examples under microscopes. They adjust sensing units in measurement gadgets. Research laboratories require this level of control. Consistent performance matters for experiments.

The demand for smaller sized, more accurate tools maintains growing. High accuracy micro rack and pinion gears meet this demand. They make it possible for finer control than various other systems. Their portable design fits tight areas. Efficiency is trusted over extended periods.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High precision micro small rack and pinion gear

What are high precision micro small rack and pinion gears made from?

These gears are usually made from strong metals. Steel is common. Stainless steel is used often too. It resists rust well. Sometimes special plastics are chosen. Plastic gears work where you need quiet operation or less weight. The material depends on the job the gear must do.

How precise are these small rack and pinion systems?

They are very precise. High precision means very little wobble or play. This play is called backlash. Good manufacturing keeps backlash extremely low. Tolerances are tight. This means parts fit together almost perfectly. This accuracy is vital for machines needing exact movement.

What load can a micro rack and pinion handle?

Load capacity changes a lot. Size, material, and tooth design matter most. Metal gears handle heavier loads than plastic ones. Small size means lower capacity than big industrial gears. Always check the maker’s specs. Pushing beyond the rated load causes early failure or poor accuracy.

Do these gears need special protection?

Sometimes yes. Normal environments might need no extra protection. Harsh conditions need it. Dust, chemicals, or moisture damage gears. Seals or special coatings help. Nickel plating protects steel gears. Special plastic types resist chemicals. Think about where the gear will work.

Can I get custom micro rack and pinion gears?

Yes, many makers offer custom solutions. You might need a special size. You might need a unique tooth shape. You might need a specific material. Custom gears solve specific problems standard ones cannot. Lead times are longer. Costs are higher than standard parts. Discuss your exact needs with the supplier.

(High precision micro small rack and pinion gear)

REQUEST A QUOTE

RELATED PRODUCTS

Hastelloy B-2 C276 C-22 Monel K500 Customized Open Die Forging Gear Ring Gear Ring for Excavator Rotary Table Application

High Efficiency Nmrv Series Involute Spur Gear Rv25 Mechanical Transmission Spare Parts Worm Gearbox Flange Output Nmrv Gearbox

Genuine K19 K38 K50 NT855 NTA855 VTA28 N14 LT10 M11 QSK19 QSK38 QSK45 QSK60 Crankshaft Gear and Crankshaft For Cummins

Metal Micro Crown Bevel Gear And Pinion Gears Differential Ring

Custom cnc machining OEM fabrications service precision cnc machining parts double spur gears steel gears