PRODUCT PARAMETERS

Description

Overview of OEM Precision Small Nylon Plastic Gear for Toy

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of OEM Precision Small Nylon Plastic Gear for Toy

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: OEM Precision Small Nylon Plastic Gear for Toysystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern OEM Precision Small Nylon Plastic Gear for Toymanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(OEM Precision Small Nylon Plastic Gear for Toy)

Specifications of OEM Precision Small Nylon Plastic Gear for Toy

These are OEM precision small nylon plastic gears designed for toys. We make them to your exact requirements. The gears are small and fit easily into toy mechanisms. They handle the demands of play well. Nylon is a strong plastic material. It resists wear and tear effectively. This means the gears last longer. They keep toys working reliably over time. The precision manufacturing is key. Each gear tooth is shaped accurately. This ensures smooth meshing with other gears. It prevents jamming or skipping. The gears run quietly. They don’t make annoying noises during play. This improves the toy experience. Nylon is also naturally lubricous. It doesn’t need extra grease or oil. This simplifies assembly and keeps the toy cleaner. The material is lightweight. It doesn’t add unnecessary bulk to toys. This helps maintain the toy’s design and feel. We offer various sizes and tooth counts. You can specify the exact dimensions you need. Common sizes range from just a few millimeters in diameter. Tooth profiles include spur gears and others. Custom shapes are possible too. Colors can be matched to your design. Standard colors are available. We can also produce specific shades. The gears are durable. They withstand impacts and drops common in toys. They resist cracking or breaking easily. This reduces toy returns and complaints. Production uses high-quality molds. This ensures consistency across every gear batch. You get the same reliable part every time. Material choice matters. Nylon offers a good balance. It is strong but not brittle like some plastics. It absorbs shocks well. It copes with temperature changes in different play environments. These gears are ideal for moving parts in toys. They work in gearboxes, drive systems, and interactive features. We focus on tight tolerances. This means the gears fit perfectly into assemblies. It minimizes wobble and ensures efficient power transfer. The surface finish is smooth. It reduces friction and helps the gears spin freely. We support OEM projects fully. Our team works closely with your engineers. We help optimize the gear design for your toy application. Prototypes are available for testing before full production. This confirms the gear performance meets your goals. We ensure reliable supply for your production lines.

(OEM Precision Small Nylon Plastic Gear for Toy)

Applications of OEM Precision Small Nylon Plastic Gear for Toy

OEM precision small nylon plastic gears are essential for toy function. These custom gears are made for toy makers. They fit specific needs in toy designs. Toy companies use them to build moving parts.

Nylon plastic works well in toys. The material is strong. It handles repeated movement without breaking. Nylon gears are quiet. They don’t make annoying grinding sounds. Kids enjoy silent toys. Nylon doesn’t need oil or grease. This keeps toys clean and safe. The material lasts a long time. Toys keep working after many play sessions.

These gears power many toy movements. Small vehicles need them. Toy cars use gears to spin wheels. Remote control cars rely on precise gear action. Robots are popular toys. Gears control arm movements. They help robot heads turn. Action figures often have moving parts. Gears make legs walk. They make hands grab things. Dolls sometimes use gears too. Dolls might wave or sit using small gears.

OEM gears are custom made. Toy designers specify the exact size needed. They choose the tooth shape. They pick the gear thickness. The hole in the center is made to fit a shaft. This ensures everything works smoothly together.

Using OEM nylon gears helps toy makers. They get reliable parts. The gears perform consistently. Assembly is easier with precise parts. Fewer toys break down. Kids stay happy. Parents appreciate durable toys. It is a cost-effective solution for quality playthings.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of OEM Precision Small Nylon Plastic Gear for Toy

What materials are these gears made from? They use nylon plastic. This material is strong. It also lasts a long time. It resists wear well. It handles friction smoothly. This is perfect for toys. Kids play rough sometimes. These gears can take it.

Can you make gears to my design? Yes, absolutely. We specialize in OEM work. That means Original Equipment Manufacturing. You tell us what you need. We make it happen. We create custom molds. Then we produce your specific gear design. We follow your drawings carefully.

How precise are these small gears? They are very precise. We make them with tight tolerances. This means the size is exact. The teeth fit together perfectly. This prevents slipping or jamming. Toy mechanisms need this accuracy. It ensures smooth operation every time.

Are nylon gears durable for toys? Yes, they are very durable. Nylon is tough. It bends a little without breaking. This is called flexibility. It absorbs shocks well. Toys get dropped. They get knocked around. Nylon gears survive these impacts better than brittle plastics. They keep toys working longer.

What is the process for ordering custom gears? First, send us your design. We review the specifications. Then we discuss the project details. We agree on the quantity needed. We confirm the schedule. We make the mold tooling. Finally, we produce your gears. We ship them directly to you. We support you throughout.

(OEM Precision Small Nylon Plastic Gear for Toy)

REQUEST A QUOTE

RELATED PRODUCTS

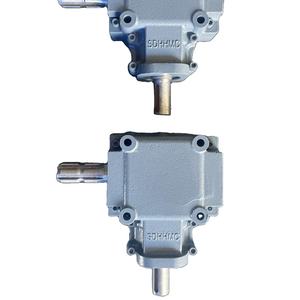

Professional Factory Nice Quality Steel Plastic Spur Gear Customized Sprocket Cnc Machining Brass Worm Gear

Steel Turboworm Gear with 20/25, 30, and 40 Tooth Ratios for Precision Farm Machinery

1-inch caliber asphalt spray gear pump, road repair high-pressure spray gear oil pump

OEM ODM Heavy Duty Steel Spur Gear Shaft for Industrial Transmission

NEMA23 Low Noise Ratio 3.25 4 5 6 10 :1 Planetary Gear Reducer Gearbox High Precision Planetary Reducer for Stepper Motor