PRODUCT PARAMETERS

Description

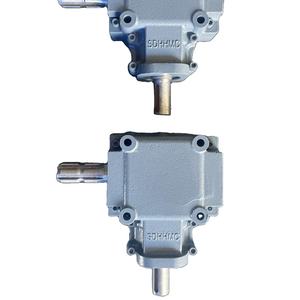

Overview of 110v 220v 380v reversible gearmotor gearhead gearbox

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of 110v 220v 380v reversible gearmotor gearhead gearbox

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: 110v 220v 380v reversible gearmotor gearhead gearboxsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern 110v 220v 380v reversible gearmotor gearhead gearboxmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(110v 220v 380v reversible gearmotor gearhead gearbox)

Specifications of 110v 220v 380v reversible gearmotor gearhead gearbox

This gearmotor suits multiple voltage needs. It works with 110V, 220V, and 380V power supplies. The reversible design allows forward and reverse rotation. Users adjust direction easily using a switch or control module. The gearbox reduces motor speed while increasing torque. This ensures smooth operation under heavy loads. Three-phase and single-phase options are available. The motor adapts to industrial and commercial settings.

The gearhead uses hardened steel gears. These handle high stress without wearing down. Precision machining ensures minimal noise during use. Lubrication is pre-applied for maintenance-free performance. Sealed housing protects internal parts from dust and moisture. This extends the product’s lifespan in harsh environments.

Torque output ranges from 10 Nm to 250 Nm. Speed options vary between 15 RPM and 600 RPM. Users select models based on load and speed requirements. The compact design saves space in tight installations. Mounting flanges fit standard equipment brackets. Wiring terminals are labeled for easy connection. Insulation materials prevent overheating during prolonged use.

Thermal protection is built into higher-voltage models. This prevents damage from overloads or voltage spikes. The motor meets international safety standards. Certifications include CE and RoHS compliance. Custom gear ratios are available for specialized tasks. The reversible function supports automation systems needing bidirectional movement.

Durability tests confirm reliable performance. The motor operates in temperatures from -20°C to 60°C. Vibration resistance keeps it stable during uneven loads. Maintenance involves occasional cleaning and lubrication checks. Replacement parts are widely accessible for quick repairs.

Applications include conveyor belts, mixers, and lifting equipment. The gearmotor integrates with machinery in food processing, packaging, and manufacturing. Its versatility suits light-duty and heavy-duty operations. Energy-efficient motors reduce power consumption. This lowers operational costs over time.

Voltage compatibility avoids the need for external converters. Users switch between 110V, 220V, and 380V without modifying setups. The gearmotor’s design prioritizes user safety. Exposed parts are insulated or shielded. Installation manuals provide step-by-step guidance. Technical support is available for troubleshooting.

The product balances power, flexibility, and reliability. It addresses diverse industrial demands. Customization options ensure it meets specific project requirements. Performance remains consistent under varying workloads. The gearmotor is a practical solution for automated systems needing precise motion control.

(110v 220v 380v reversible gearmotor gearhead gearbox)

Applications of 110v 220v 380v reversible gearmotor gearhead gearbox

110V 220V 380V reversible gearmotor gearhead gearboxes work in many industrial and commercial settings. These motors adjust speed and torque for machinery. They power conveyor belts in factories. They control lifting systems in warehouses. They drive mixers in food processing plants. The reversible feature lets the motor switch direction quickly. This is useful for tasks needing back-and-forth movement.

These gearmotors handle different voltage options. 110V suits small workshops or home projects. 220V fits mid-sized equipment like packaging machines. 380V supports heavy industrial machines such as crushers or presses. Users choose the voltage based on power supply and task demands. The gearbox reduces motor speed. It increases torque output. This makes the system efficient for heavy loads.

Durability is key for harsh environments. The motors resist dust moisture and high temperatures. They require minimal maintenance. Sealed housings protect internal parts. This extends the motor’s lifespan. Energy efficiency lowers operating costs. The design reduces wear on components.

Automation systems rely on these gearmotors. They control robotic arms in assembly lines. They adjust angles in solar panel trackers. They operate gates in water treatment plants. Agriculture uses them for irrigation pumps and harvesters. Construction equipment like cranes and winches depends on their torque.

The reversible function adds flexibility. It allows quick changes in direction without stopping the motor. This is critical for sorting systems or bidirectional conveyors. Emergency stops or process adjustments become smoother.

Gear reduction ratios vary. Users select ratios based on speed and torque needs. Higher ratios provide more torque for slow heavy tasks. Lower ratios suit faster lighter operations. The gearbox design ensures smooth power transfer. It minimizes vibration and noise.

These motors integrate with control systems. Sensors and PLCs manage their operation. This enables precise automation. Custom mounting options fit different setups. Compact designs save space in tight installations.

Voltage compatibility ensures global use. 110V matches residential standards in some regions. 220V and 380V align with industrial power grids. The motors adapt to regional electrical infrastructure. This reduces the need for voltage converters.

Reliability is critical for continuous operations. These gearmotors reduce downtime. They handle repetitive tasks without overheating. Routine checks ensure peak performance. Lubrication and part inspections maintain efficiency.

Versatility makes them ideal for diverse industries. They meet demands in manufacturing agriculture and energy sectors. Their robust construction and adaptable features support complex workflows. Users benefit from consistent output and reduced energy waste.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of 110v 220v 380v reversible gearmotor gearhead gearbox

What is the purpose of different voltage options (110V, 220V, 380V) in reversible gearmotors? The voltage options let the gearmotor work in different power supply setups. 110V is common in homes or small workshops. 220V and 380V suit industrial settings with higher power needs. Picking the right voltage ensures the motor runs safely and efficiently. Always check the power supply before installing the gearmotor.

How does the reversible function work in these gearmotors? The motor changes direction by swapping the electrical connections. A switch or controller reverses the polarity. This lets the motor spin clockwise or counterclockwise. Reversing is useful for tasks needing bidirectional movement, like conveyor belts or lifting systems. Follow the wiring diagram to avoid damaging the motor.

Can these gearmotors handle heavy loads? Yes. The gearbox reduces speed and increases torque. This makes the motor strong enough for heavy machinery. Load capacity depends on the gear ratio and motor size. Check the product specs for maximum load limits. Overloading the motor can cause overheating or gear damage.

Are these gearmotors easy to install and maintain? Installation requires basic mechanical and electrical skills. Mount the motor securely and connect wires as instructed. Maintenance includes lubricating gears and checking for wear. Clean the motor regularly to prevent dust buildup. Follow the manual for service intervals. Proper care extends the motor’s lifespan.

What industries use these gearmotors? They are used in manufacturing, agriculture, construction, and automation. Common applications include mixers, conveyors, hoists, and packaging machines. The reversible feature and multiple voltage options make them flexible for different tasks. Choose a model that matches your industry’s power and torque requirements.

(110v 220v 380v reversible gearmotor gearhead gearbox)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision Gear Rack Alloy Steel High Quality Material Gear Rack CNC Machine Tool Industrial Equipment Gear Rack

OEM ODM Heavy Duty Steel Spur Gear Shaft for Industrial Transmission

SLTM gear reduction box

Accessories Planetary Speed Reducer Helical Worm Speed Reducer Agricultura Auto Transmission Gearbox Parts Reduction

Metal Micro Crown Bevel Gear And Pinion Gears Differential Ring