PRODUCT PARAMETERS

Description

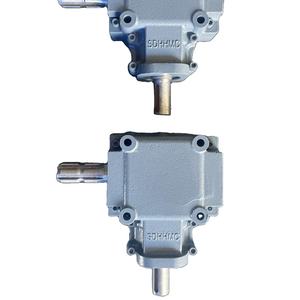

Overview of HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gearsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gearmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear)

Specifications of HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear

The HXMT High Accuracy Spiral Bevel Steel Gear from Shenzhen is designed for sturdy industrial applications. It is made from state-of-the-art carbon steel. This product makes sure strength, toughness, and resistance to put on. The gear measures 1 meter in size. It supports loads up to 30 lots. The tooth density is 6mm. This style balances weight capacity with precision.

The spiral bevel shape boosts power transmission performance. It enables smooth interaction between gears. This lowers noise and vibration during operation. The equipment is ideal for high-torque systems. It does well under constant tension. The surface area is heat-treated. This boosts solidity and expands service life.

Manufacturing utilizes sophisticated CNC machining. Tolerances are firmly controlled. This makes certain exact tooth profiles. Each gear undergoes extensive quality checks. Dimensions, surface finish, and solidity are checked. The result corresponds efficiency in demanding settings.

Applications consist of mining equipment, building equipment, and marine propulsion systems. The equipment fits heavy-load circumstances. It operates in severe conditions such as heats or messy environments. Maintenance demands are low. Appropriate lubrication makes certain lasting reliability.

Personalization is offered. Alterations to tooth angle, bore size, or installing holes can be made. This flexibility fulfills particular machinery requirements. The gear is compatible with different commercial configurations.

Quality certifications comply with global requirements. Evaluating includes load-bearing tests and fatigue evaluation. Each unit is examined before delivery. Product packaging uses anti-corrosion products. This avoids damage throughout transit.

The HXMT gear supplies an affordable solution. It combines robust building and construction with accuracy design. Industries benefit from minimized downtime and enhanced functional effectiveness. Technical assistance is given by the manufacturer. Aid covers installation advice and troubleshooting.

Dimensional precision guarantees seamless integration with existing systems. The equipment’s design minimizes power loss. This contributes to decrease operational expenses. Efficiency continues to be steady under variable speeds. It takes care of abrupt lots modifications without failing.

Material sourcing adheres to rigorous protocols. Raw carbon steel is examined for pollutants. This ensures architectural stability. Production processes focus on ecological sustainability. Waste materials are recycled. Energy-efficient techniques lower the carbon impact.

The equipment’s design reduces placement challenges during installation. It simplifies upkeep treatments. Replacement intervals are much longer contrasted to typical gears. This decreases lasting ownership costs.

(HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear)

Applications of HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear

The HXMT high-precision spiral bevel steel equipment from Shenzhen is developed for durable industrial applications. This 1-meter-diameter gear handles lots up to 30 tons. It is made from 6mm carbon steel, making sure toughness and resistance to put on. The spiral bevel design boosts power transfer effectiveness, making it ideal for high-torque atmospheres.

This equipment is used in mining tools, building and construction machinery, and large production systems. Its precision design allows smooth procedure under extreme anxiety. The carbon steel material gives high stamina, lowering the threat of contortion. Surface area therapies like warmth hardening improve longevity, also in extreme problems.

In wind generators, the equipment sustains blades shaft positioning, enhancing power output. Its corrosion-resistant coating secures versus wetness and environmental damages. The spiral bevel structure minimizes noise during procedure, suitable for metropolitan framework tasks. Personalized tooth accounts ensure compatibility with existing equipment.

The auto sector utilizes this equipment for hefty lorry transmissions. It enhances load circulation, lowering strain on engine parts. The exact tooth engagement decreases vibration, boosting vehicle driver comfort. Manufacturers take advantage of minimized upkeep expenses because of its robust design.

Aerospace applications consist of helicopter blades systems and landing equipment mechanisms. The gear’s lightweight yet strong construction meets strict air travel criteria. Tight tolerances throughout production warranty reputable efficiency in crucial procedures.

Marine tools relies upon this equipment for steering systems and propulsion devices. Saltwater-resistant materials stop corrosion, extending life span. The spiral bevel design ensures effective power transfer in confined spaces.

Industrial robotics utilize the equipment for accurate joint activities. High positional accuracy sustains repetitive tasks in production line. The low-friction surface area treatment decreases power loss, boosting functional effectiveness.

Agricultural equipment benefits from the equipment’s ability to take care of irregular tons. It is frequently discovered in tractors and harvesters, sustaining heavy tillage and planting operations. The resilient building and construction stands up to dirt, particles, and variable weather.

Railway systems incorporate the gear right into locomotive engines and freight carriers. It guarantees steady power transmission across long-distance courses. Normal lubrication periods are expanded due to the equipment’s wear-resistant buildings.

The HXMT equipment is examined for top quality at numerous production phases. Advanced CNC machining guarantees uniformity in large-scale orders. Technical support is readily available for setup and troubleshooting, making sure minimal downtime.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear

The HXMT High Precision Spiral Bevel Steel Gear is designed for heavy-duty industrial use. It is made from carbon steel. The gear measures 1 meter in diameter. It handles loads up to 30 tons. The tooth thickness is 6 millimeters. This gear is built for durability. It works in high-stress environments like mining equipment or construction machinery.

What materials are used in this gear? The gear uses carbon steel. Carbon steel is strong. It resists wear. It handles heavy loads. This material is reliable. It performs well under extreme conditions. Carbon steel is cost-effective. It balances strength and affordability.

Where is this gear commonly used? It is used in heavy machinery. Examples include mining drills or cement mixers. It fits systems needing high torque. The spiral bevel design transfers power smoothly. It reduces vibration. This gear suits applications requiring precise motion control.

Why is precision important in this gear? Precision ensures efficient power transfer. It reduces energy loss. Tight tolerances prevent misalignment. Misalignment causes wear. Wear leads to breakdowns. The HXMT gear is machined with advanced CNC technology. Each tooth is checked for accuracy. This guarantees long-term performance.

Does the gear require special maintenance? Regular inspections are needed. Check for signs of wear. Lubricate the teeth periodically. Use high-temperature grease. Avoid overloading beyond 30 tons. Clean debris from the gear teeth. Proper maintenance extends service life.

Can this gear be customized? Yes. Custom sizes are available. Modifications include different bore sizes or tooth profiles. Special coatings can be added. Coatings prevent rust. They reduce friction. Custom orders require detailed specifications. Lead times vary based on complexity.

(HXMT From Shenzhen High Precision Spiral Bevel Steel Gear 1m 30t-6mm Carbon Steel Spiral Bevel Gear)

REQUEST A QUOTE

RELATED PRODUCTS

Genuine K19 K38 K50 NT855 NTA855 VTA28 N14 LT10 M11 QSK19 QSK38 QSK45 QSK60 Crankshaft Gear and Crankshaft For Cummins

Existing goods high quality C45 steel spur gear racks M1 10*10*500

Gear Rack Pinion For Linear Motion Cnc Machine Helical Tooth Rack And Pinion Gear

Standard Quality Medium Carbon Steel Starter Ring Gear for Automobile and Agriculture Industry Available at Reasonable

NEMA23 Low Noise Ratio 3.25 4 5 6 10 :1 Planetary Gear Reducer Gearbox High Precision Planetary Reducer for Stepper Motor