PRODUCT PARAMETERS

Description

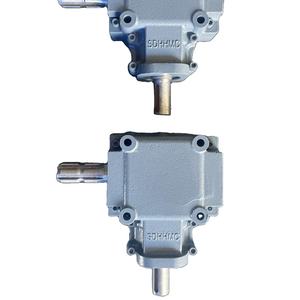

Overview of TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated

Gears are mechanical elements that are typically used to transmit rotational motion and force. They work by meshing teeth with each other to change speed, direction of torque, or to transfer power between multiple shafts. Gears are an integral part of mechanical engineering and are widely used in a variety of mechanical devices.

Advantages and features of TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated

Efficient transmission: Gears are capable of directly converting power with high efficiency and low energy loss.

Precise ratios: the desired ratio of speed and torque can be obtained by selecting gears of different sizes.

Compact: TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicatedsystems take up less space than other forms of power transmission.

High durability: well-designed gears can operate stably for long periods of time in harsh environments.

Low noise and vibration: Modern TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicatedmanufacturing technology ensures smooth operation and reduces noise and vibration.

Various types: Spur, helical, and bevel gears are available depending on the application scenario.

(TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated)

Specifications of TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated

The TILI TD Series Precision Planetary Reducer is designed for integration with servo motors and stepper electric motors. It delivers high-precision movement control in commercial automation systems. This gearbox handles hefty lots while preserving security. Its small structure suits applications where area effectiveness issues. The reduction ratios range from 3:1 to 100:1. Customers can pick the ratio based on torque and speed needs. The optimal outcome torque reaches 200 Nm. This guarantees dependable performance sought after settings.

The transmission utilizes alloy steel gears. These gears undertake precision grinding. This improves meshing accuracy. It lowers noise throughout procedure. The housing is light weight aluminum alloy. This product integrates lightweight residential properties with high rigidity. It resists deterioration. The input and result shafts are hardened. This extends service life. The design includes sealed bearings. These stop dirt and particles ingress. Lubrication is maintenance-free. This minimizes downtime.

Reaction is minimized to listed below 10 arcmin. This guarantees specific positioning. Effectiveness exceeds 95%. Energy loss is reduced. Warmth generation stays controlled. The TILI TD Collection supports bidirectional rotation. It fits axial and radial loads. Installment is versatile. Customers can place it horizontally or vertically.

This reducer collaborates with robotic arms. It fits CNC machinery. It applies to packaging devices. Medical gadgets gain from its precision. Automated production lines use it for consistent performance. Custom-made alterations are offered. Shaft dimensions and flange kinds can be changed. Special oil choices suit extreme temperature levels.

The item satisfies ISO 9001 criteria. It complies with CE accreditation demands. Examining consists of vibration analysis. Lots endurance trials make sure integrity. Each unit goes through top quality checks before delivery. Technical assistance covers installation support. Troubleshooting aid is given. Extra components are accessible worldwide.

Longevity is evaluated under variable rates. Shock resistance deals with abrupt load changes. Long-term procedure shows very little wear. Performance remains steady with time. The TILI TD Collection equilibriums price and capability. It deals with requirements across sectors.

(TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated)

Applications of TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated

The TILI TD Series Accuracy Planetary Reducer delivers high-performance movement control remedies for commercial automation. It incorporates perfectly with servo motors and stepper electric motors. This transmission guarantees exact torque transmission and steady operation in demanding environments. Designers rely on its small design and high decrease ratios to enhance equipment efficiency. The product matches applications calling for accuracy, sturdiness, and minimal maintenance.

Robotics systems take advantage of the TD Series. It gives smooth motion control for robotic arms and joints. The precision reduces placing mistakes throughout repetitive jobs. High torque thickness permits compact robotic layouts without compromising power. Factories use these reducers in production line to boost production rate and uniformity.

Industrial automation tools depends upon the TD Series for trustworthy power transmission. Conveyor systems, CNC devices, and printing gadgets use it to preserve consistent speeds under heavy loads. The global equipment structure lessens backlash, making certain exact positioning in automated processes. Makers value its capability to handle sudden load adjustments without efficiency loss.

Packaging equipment needs consistent rate control for loading, sealing, and labeling. The TD Collection adapts to variable functional needs. Its high decrease ratios allow great changes in electric motor outcome. This minimizes product waste and downtime. Food and pharmaceutical markets prioritize its corrosion-resistant designs for hygienic atmospheres.

Renewable energy systems make use of the TD Series in solar trackers and wind generator pitch controls. The gearbox stands up to harsh weather condition while maintaining angular accuracy. Its efficiency maximizes energy capture in solar panels and supports turbine blade angles during wind changes.

Medical devices utilize the reducer’s accuracy for imaging systems and medical robots. Low-noise procedure makes certain individual comfort. High rigidness warranties repeatable movements in important procedures. Laboratories integrate it into diagnostic equipment to boost testing integrity.

The TD Collection supports aerospace testing gears and satellite positioning mechanisms. Designers trust its longevity under severe temperature levels and resonances. Personalized reduction proportions match specific torque and rate demands. This flexibility simplifies combination into specific tasks.

Product handling devices like cranes and lifts uses the TD Series for secure lots monitoring. The gearbox avoids unexpected shifts throughout upright transport. High overload ability secures systems from damages throughout unanticipated tension. Warehouses achieve smoother logistics operations with reduced mechanical wear.

Automotive assembly line apply the reducer in welding robots and accuracy marking machines. Consistent torque outcome guarantees uniform weld high quality and part measurements. The small size conserves area in jampacked factory formats. Electric vehicle manufacturers adopt it for battery setting up processes needing delicate handling.

The TD Series global transmission satisfies varied commercial needs through adaptable design and robust engineering. Its compatibility with servo and stepper electric motors makes it an universal option for boosting motion control accuracy.

Campony Introduction

Established in 2002, Shift Gear Machinery Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated

What is the TILI TD Series Precision Planetary Reducer used for? The TILI TD Series reduces speed and increases torque in machinery. It connects directly to servo or stepper motors. Common uses include robotics, CNC machines, packaging systems, and automated production lines. The design ensures precise motion control. It handles high loads efficiently.

How durable is the TILI TD Series gearbox? The gearbox uses high-strength alloy steel gears. These undergo precision grinding and heat treatment. Hardened surfaces resist wear. Sealed bearings prevent dust or moisture damage. Testing shows reliable performance under heavy loads. It operates smoothly in temperatures from -20°C to 120°C.

How do I pick the right reduction ratio? Check the motor’s speed and torque requirements. Higher ratios lower output speed but boost torque. Match the ratio to your machine’s load demands. Common ratios range from 3:1 to 100:1. Refer to the product manual or contact support for specific applications.

Can the TILI TD Series work with any servo or stepper motor? Yes. It fits most standard servo and stepper motors. Confirm the motor’s flange size and shaft dimensions before installing. Custom adapters are available for non-standard models. Proper sizing ensures optimal performance. Always check compatibility guides first.

Does the gearbox need regular maintenance? No. The unit comes pre-lubricated and sealed. No routine maintenance is required. Inspect it periodically for physical damage or unusual noise. Re-lubrication might be needed after 10,000 hours of use. Follow the manual’s guidelines for lubrication types and intervals.

(TILI TD Series Precision Planetary Reducer Planetary Gearbox Reducer Reduction Ratio Servo Motor Stepper Motor Dedicated)

REQUEST A QUOTE

RELATED PRODUCTS

Mine Equipment Spare Parts Large Diameter gear Wheel High Quality Spur Casting Large Gear Wheel

heavy-duty single two three stage helical bevel cylindrical harden softened gear speed reducer reduction gearbox

Good Quality Wear-resistant AB Serious Helical Gears Planetary Gearbox

Custom Gear Speed Reducers 10-60 ratio WPA Worm Gearbox single speed Reducer

Custom CNC Machining Engine Gear s Gearpinion Parts Metal Mini Gears